PSYCLOPS: AR TECH TRAINING

Creative Direction | 3D Modeling/ Animation | UI/UX | Mixed Reality

Tech Training

There has been an increasing need for on-job training in the industrial space. Augmented Reality (AR) Mixed Reality (MR) has become a safer way to inform, educate employees, support engineers, increasing productivity and quality inspections. It can be used to improve your training offering, drive behavior change and create lasting business impact.

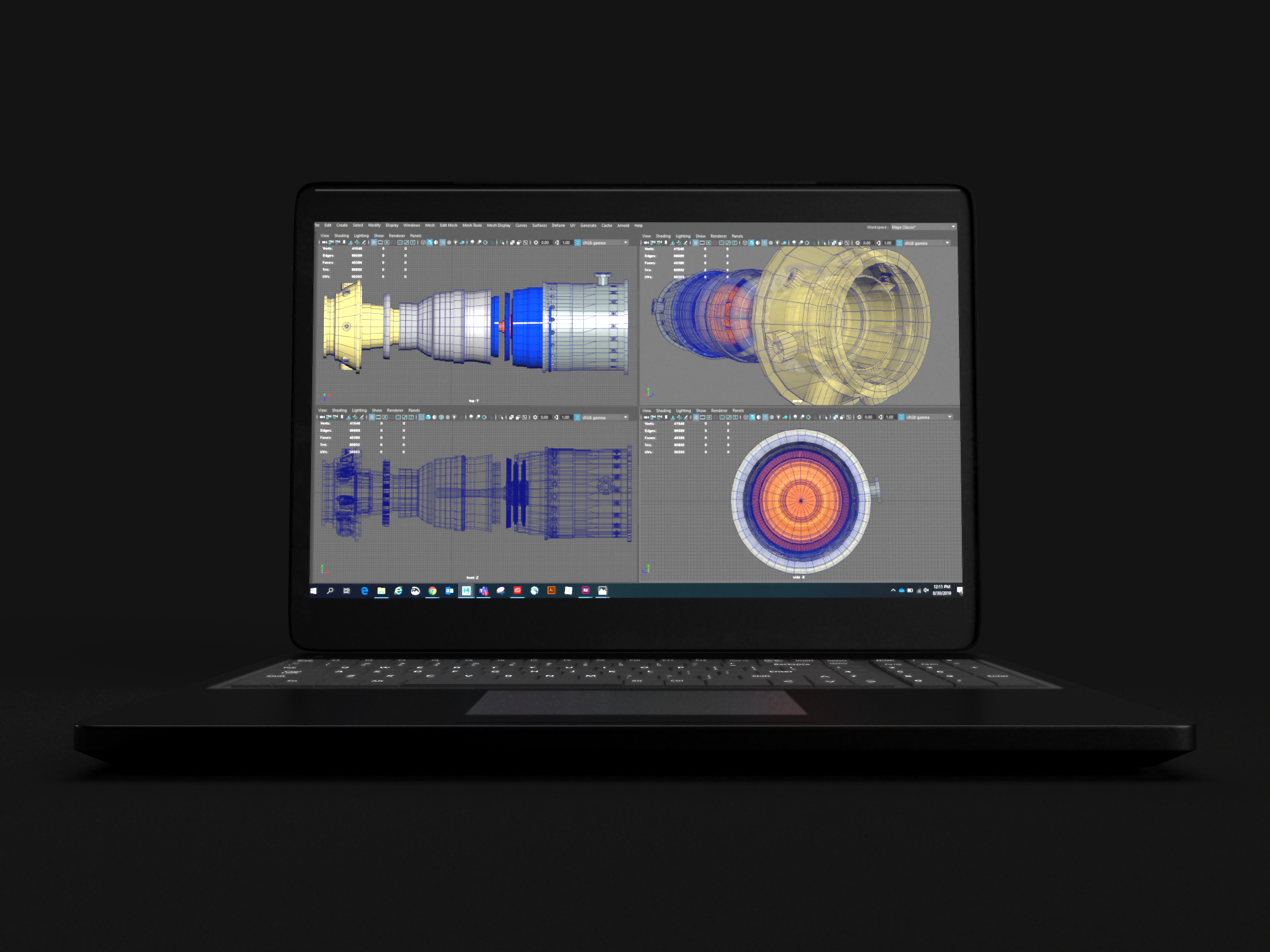

3D Modeling

The first step was to remodel the combustion section of a gas turbine engine from CAD files to low poly models in Autodesk Maya to be imported into Unity for use in Augmented Reality (AR) headsets. Each major part was rebuilt and reduced to the lowest reasonable poly count to maximize frame rate in Unity. They were then reassembled into their correct positions. .

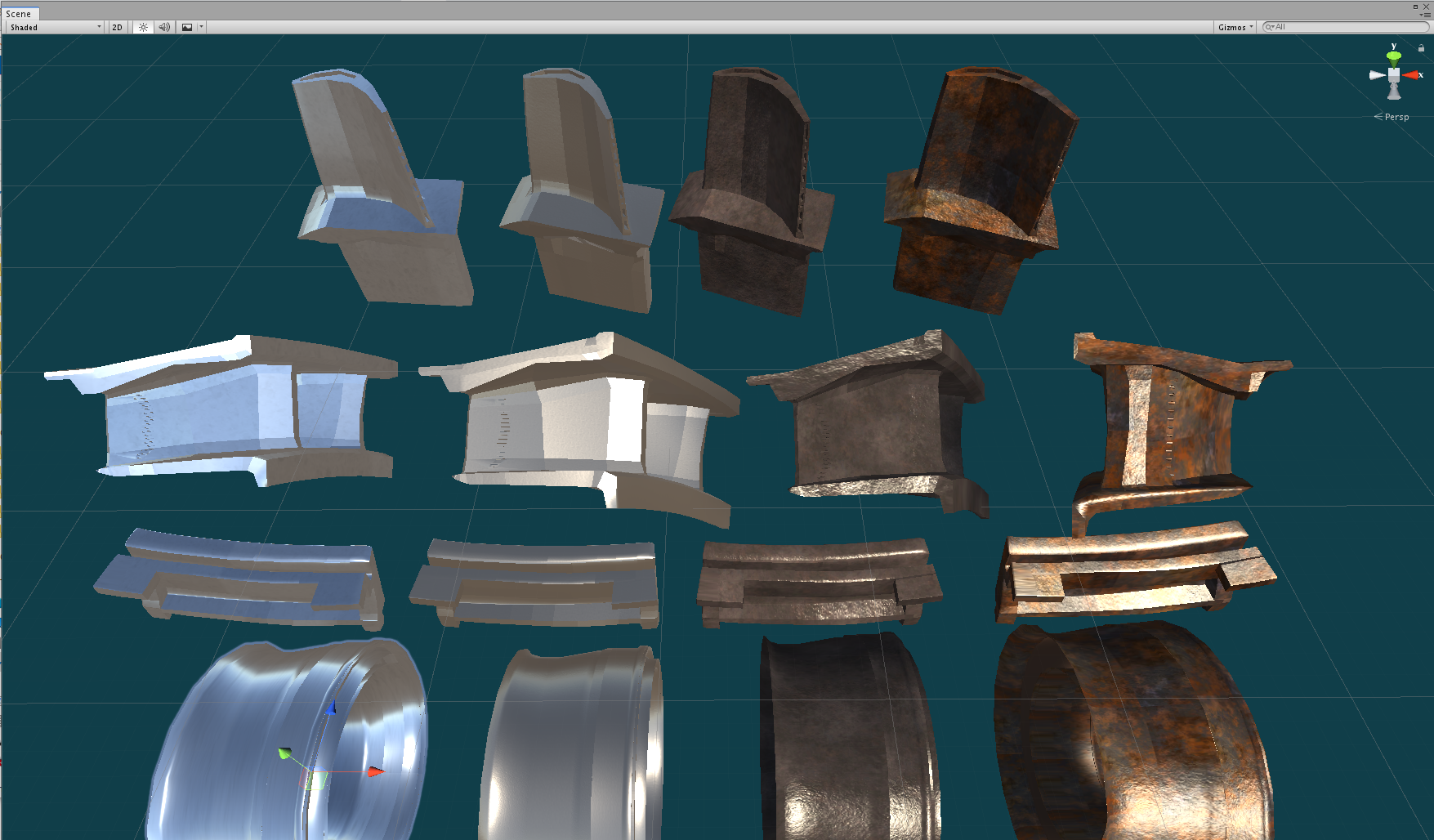

UV Mapping

The engine parts of interest were photographed using the borescope and used as a point of reference for UV mapping. This helped to demonstrate the different levels of corrosion that the engine parts could take on, so that the trainee knew what to look for when inspecting the machine through the borescope. The “Non Conformance” types ranged from new, distressed to severe corrosion.

UI / UX

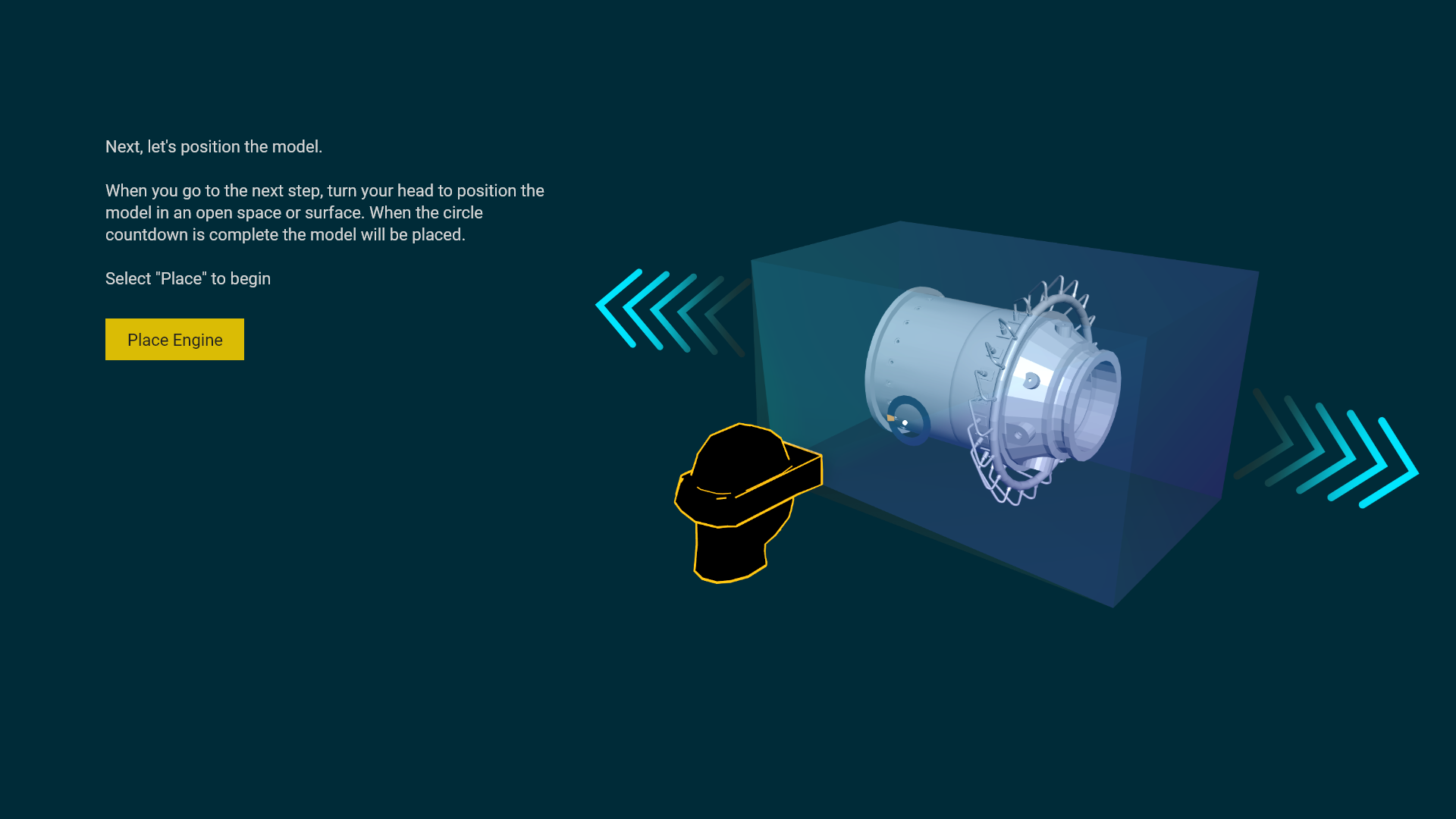

Engineers werw interviewed in order to have a better understanding of the inspection process. From there UX and UI boards were created of the entire workflow, approved and sent to dev for implementation. These took on many iterations working collaboratively with the team and stakeholders. There were two main courses, which were the Exploration and the Activity Test. Exploration is a walkthrough to familiarize engineers what the ports of entry for inspection and what those parts are to be inpected. The Activity Test will test your knowledge on what the student has learned.

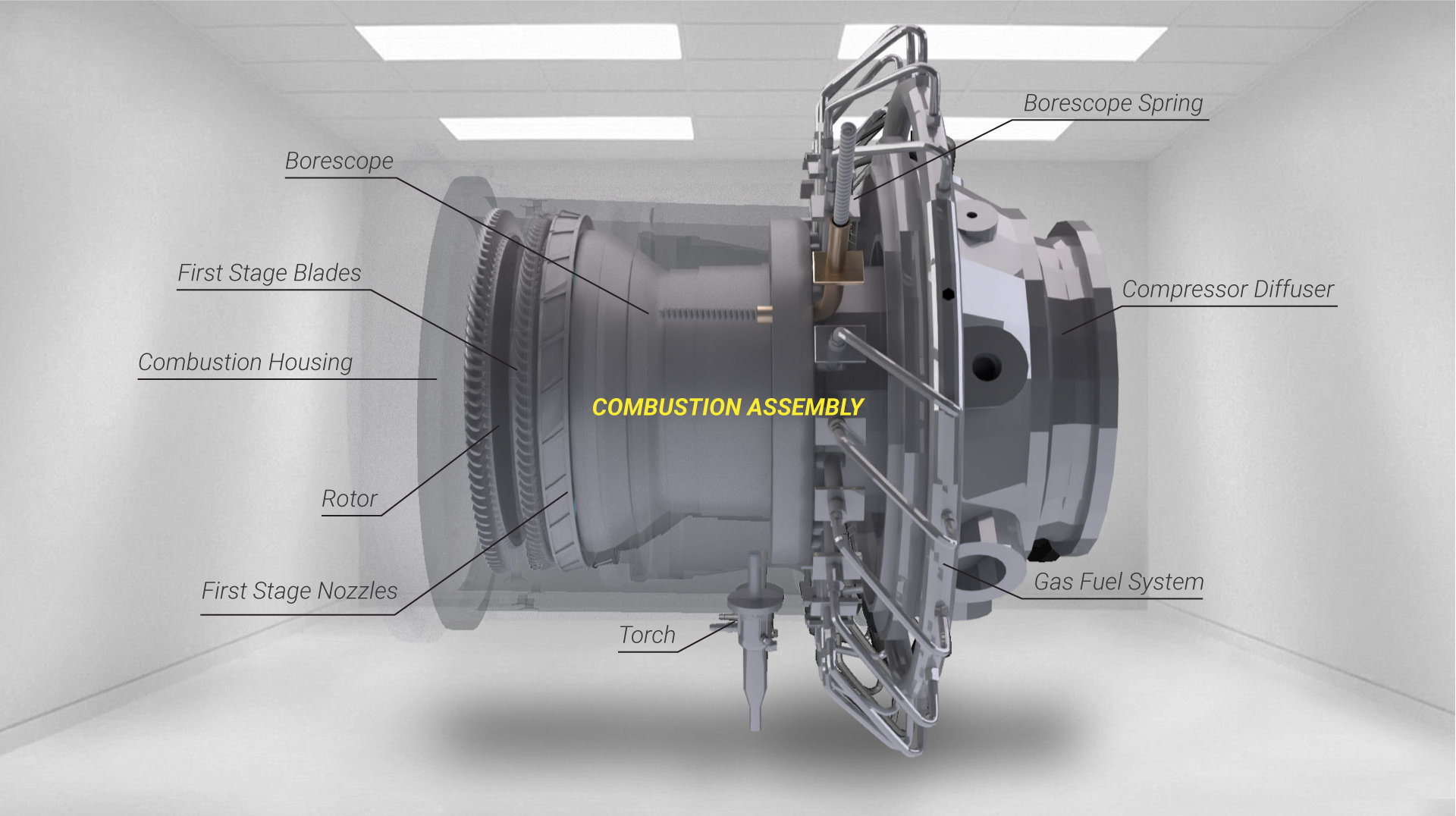

Borescope Inspection POV

For an added experience, the point of view of the borescope is similated in this video to give the trainee an idea of what they would be observing and what parts to inspect while it is directed through the point of entry, labeling the part names.